How to choose the cabinet material like a pro? Part 2:

As we have already discussed about the Solid Wood in the previous post , in continuation of the series ,now let us discuss about the engineered wood.

1.b. Engineered wood:

It is a manmade wood manufactured by using different materials such as shredded wood fibers, sawdust, adhesives and various chemicals. It can be cut and worked similar to the solid wood. All engineered woods require a laminate, paint or veneer etc. to cover both sides of the sheet.

1.b.i. Particle board:

Manufactured by pressing and extruding wood wastes like sawdust, sawmill shavings and wood chips by binding with synthetic resin. Generally, particle boards are available with prelamination called as prelaminated particle boards.

Is particle board recommended for kitchen cabinets ?

Let us discuss the pros and cons of particle boards before arriving at a conclusion.

Particle board is generally not recommended as a kitchen cabinet material due to its susceptibility to moisture damage and low strength but don’t assume that particle board is all bad, if the Particle board is laminated with melamine, called as melamine particle board and if the edges are perfectly sealed then it can be used in some places in kitchen like shutters of overhead cabinets.

1.b. ii. Medium Density Fiberboard (MDF):

Wood residues are broken down into wood fibers and combined with wax & a resin binder, later forming it into panels by applying high temperature and pressure.

Is MDF recommended for kitchen cabinets?

Will arrive at the conclusion after discussing the pros and cons of it

MDF is not recommend by carpenters and many interiors in the market, by magnifying the cons of it. But most of them are only half-truths because manual carpenters generally use nails as a joinery whereas nailing on MDF edges would chip and splinter the edges. Nails are not recommended with MDF.

MDF panels require machines to process which carpenters and many interiors do not have. To add further, the carpenters and majority of interiors in Hyderabad and India are not aware of the scientific advances made in the manufacturing of MDF and still cling on to their traditional opinions. Carpenters and many interiors in India work like a hand in glove as they both are interdependent. Regarding the moisture resistance – now a days water resistant MDF is also available in the market, and is manufactured by reputed brands like Century and Greenpanel etc, thanks to the scientific advancement. When it comes to strength, how much weight a cabinet have handle? hardly 30-50 kg, which the MDF can easily take if the cabinet is well built.

MDF gives super fine finish with paint like lacquer, duco and PU. MDF can be carved to create any design of our liking. The conclusion is, MDF can be used on all the other places leaving the places where exposure to moisture is high like under sink cabinet and under kitchen counter tops etc. MDF as a cabinet material is especially recommended if someone is on a budget. Some finishes like PU/Duco/Lacquer are best achieved with MDF than plywood, so in this case carcass can be made with other materials like plywood and shutters can be made with MDF to achieve desired look.

1.b.iii High Density Fiber board (HDF):

It is an improvised version of MDF, more durable and denser than MDF. Generally, HDF is used as laminate flooring material and cladding material all over the world. it can also be used as a cabinet material but at this price range better alternatives like ply wood and HDHMR are available in the market with better properties especially moisture resistance.

1.b.iv plywood:

Plywood is manufactured from thin layers or “plies” of wood veneer that are glued together (by using resins) with adjacent layers having their wood grain rotated up to 90 degrees to one another. These layers in plywood are visible on the edges.

Plywood is the most preferred cabinet material in india due to its advantages over many other engineered wood. Many variants of plywood are available in India vis commercial ply, MR( Moisture resistant ,BIS 303 ) grade , BWR ( Boiling water resistant BIS 303) and BWP ( Boiling Water Proof BIS 710) or Marine grade. The quality of plywood depends on its grade & veneer. Gurjan is the most popular veneer used to manufacture plywood in India. The grades and types of plywood will be explained in a separate post.

Is Plywood recommended for kitchen cabinets?

let us check the Pros and Cons of plywood first.

Plywood is highly recommended by the carpenters and interior designers in India due to its shear strength to withstand nails and screws effectively. Carpenters mostly use nails as joinery material (though not recommended as it splits the edges) because it reduces time and effort to join boards that make a carcass/box.

Plywood is a well recommended material for kitchen cabinets, if the design style demands paint finish like PU or Duco etc. than shutters can be made with materials like MDF or HDHMR etcetera to achieve the desired look. While selecting the plywood, Care needs to be taken with regard to its quality as the market is flooded with many substandard ply variants.

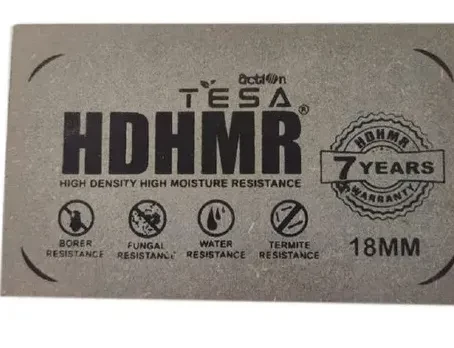

1.b.v High Density High Moisture Resistance (HDHMR) Board:

It is an advancement of MDF and HDF boards in terms of Moisture resistances and screw holding strength. It is relatively a new product in the market and within a short span of time it has gained a lot of popularity and is giving very tough competition to the plywood which is considered as one of the best cabinet materials in India.

Is HDHMR recommended for kitchen cabinets?

Now let us check the suitability of HDHMR as a cabinet material by assessing the Pros and Cons

HDHMR is well recommended as a kitchen cabinet material and if someone is on budget then cabinet can be made with ply (in Kitchen) or with MDF ( in dry places like wardrobes ) and shutters can be made with HDHMR due to its ability to give a perfect finish.

With this post, different types of engineered wood and each variants pros and cons has been explained. Next post is on plastic composite materials and metal-based materials.